Equipment construction details are an important part of food handling applications. Understanding material surface finishes, weld types, and frame styles are important aspects of design and fabrication choices that go into your equipment selection process.

Welds, Finishes and Design Packages

STAINLESS STEEL SHEET FINISHES

Glass bead blast

No.4 (brush polish)

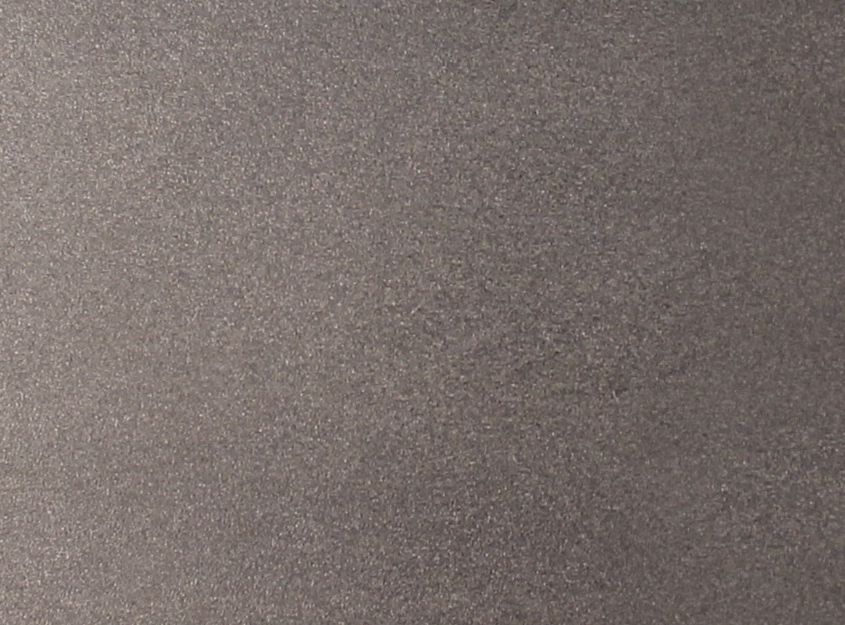

No. 2B (mill)

Mill Finish

- Surfaces will have an inconsistent appearance with varying uniformity, especially between Sheet and Structural materials

- Will include minor surface scratches

#4 Polished

- Sheet steel surfaces will have a consistent brushed appearance with minor varying uniformity, primarily between Sheet and Structural materials

- Will include minor surface scratches

Glass bead blast

- Specified surfaces are bead blasted which results in a more consistent surface texture with a more uniform deeper gray appearance.

Passivation

- Dissolves free iron impurities and helps restore the corrosion protection provided by the passive surface layer.

- Specified surfaces are passivated after cleaning, grinding, and/or bead blasting processes are completed.

WELDS

Stitch Weld

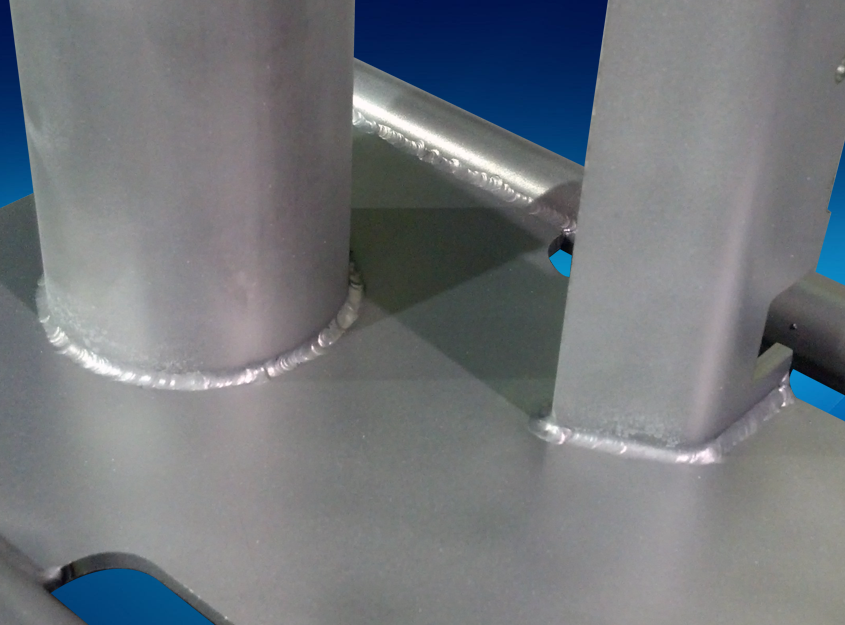

Stitch Weld

Continuous Weld

Continuous Weld

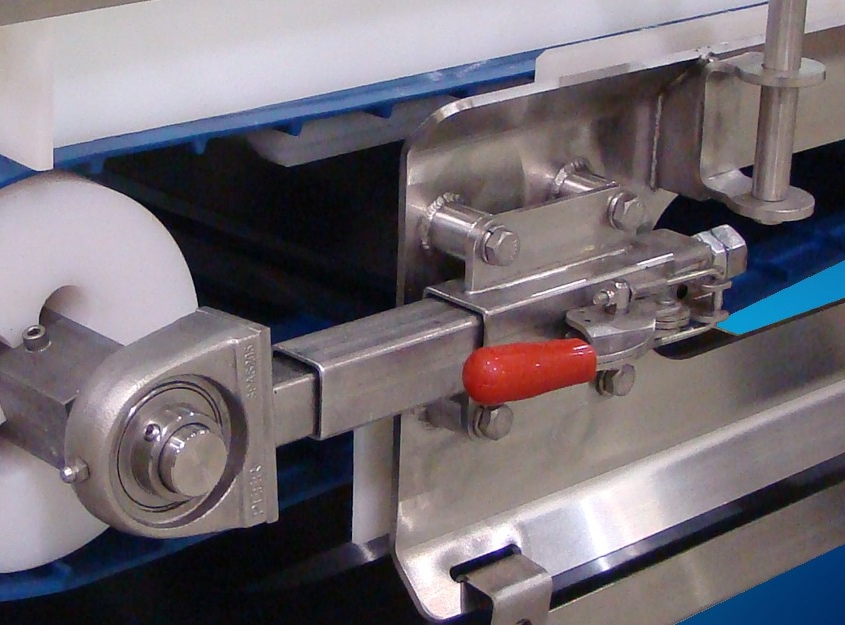

Stitch

- Welds are intermittently spaced along the joint

- Welds may include minor imperfections, pits, crevices, small pockets, and scratches

Continuous

- Welds are continuous along the joint

- Welds may include minor imperfections, pits, crevices, scratches and small pockets

WELD FINISH

Cleaned

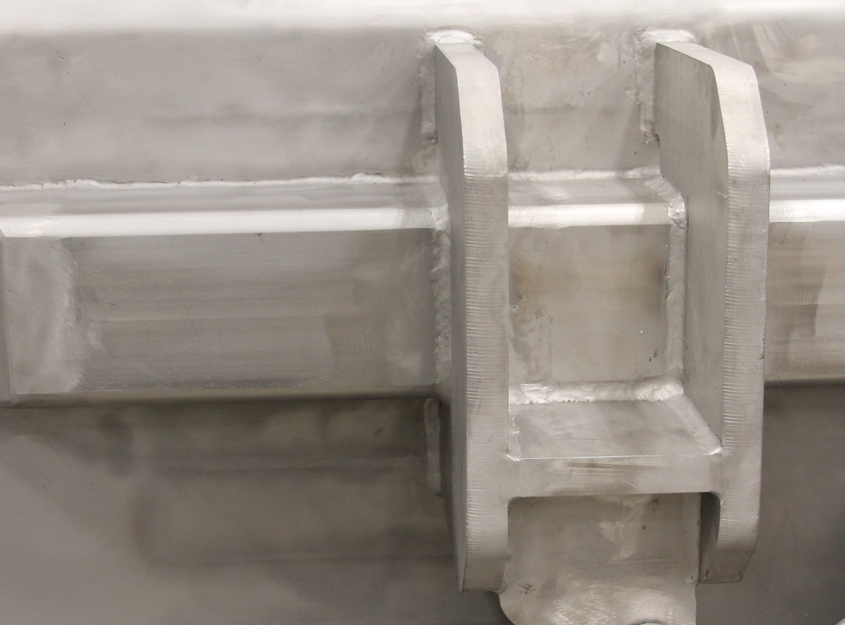

Coarse ground and cleaned

Coarse ground and cleaned

Cleaned

- Mechanically cleaned to remove spatter

- Glass Bead blasted and/or Electrostatically cleaned to remove heat tint discoloration

Coarse ground and cleaned

- Welds are ground to reduce imperfections typical of most welds

- May include minor imperfections, ripples and scratches

- Welds are ground to a 250 RA micro finish or better

- Glass Bead blasted and/or Electrostatically cleaned to remove heat tint discoloration

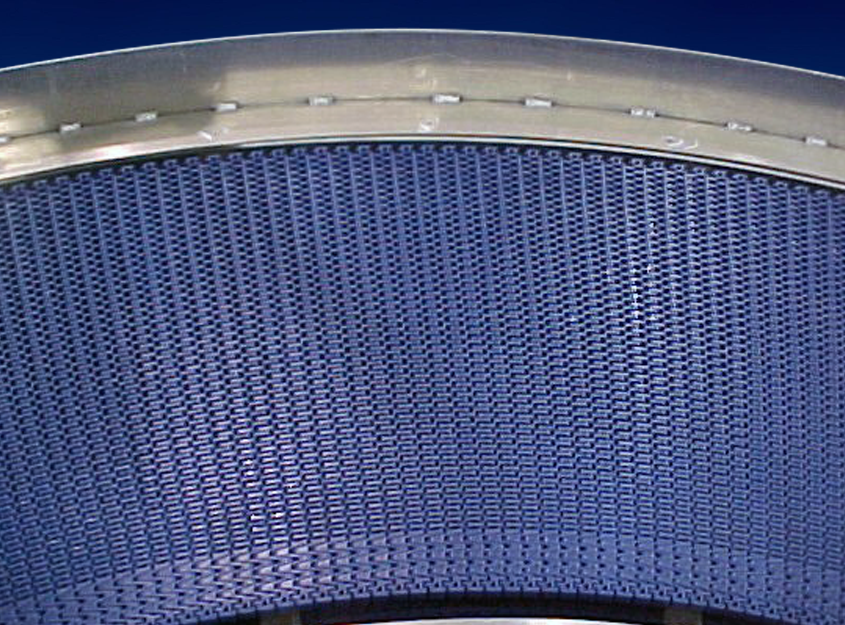

BELT CONVEYOR AND DUMPER STANDARD DESIGN PACKAGES

Hygienic Level I for Dry Environments – Carbon Steel, FDA Powder Coated Frame, Legs or Drum , Stainless Steel Shafts with FDA Materials, Non-Washdown Drive or Power Unit, Epoxy Painted Hydraulic Cylinders, FDA Belting, FDA-H1 Lubricants, NEMA-1 Electrical/Control Items, Stitch Welded Construction

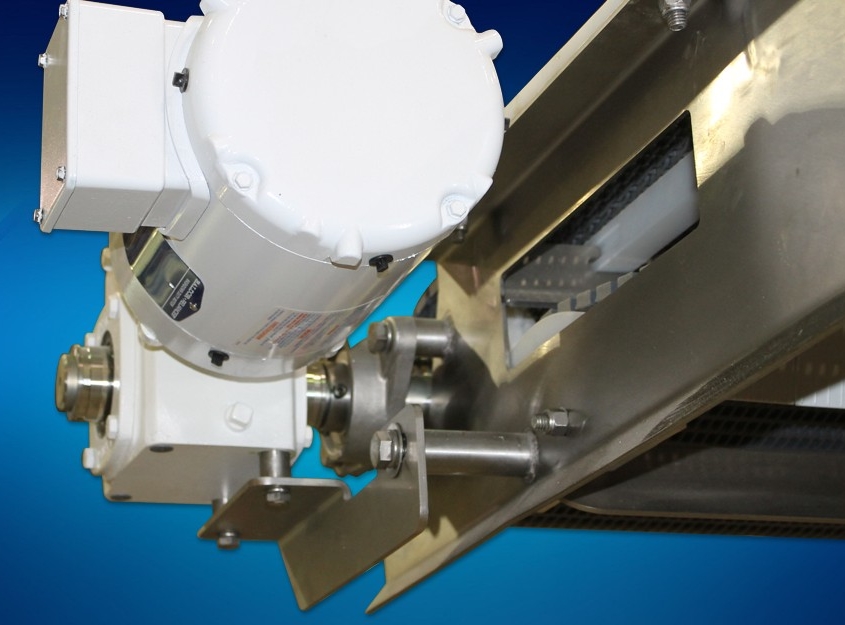

Hygienic Level II for Dry to Wet Environments – Stainless Steel 2B Mill Finish Frame/Legs or Drum, Stainless Steel Shafts with FDA Materials, Epoxy Painted Washdown Drive or Power Unit, Epoxy Painted Hydraulic Cylinders, FDA Belting, FDA-H1 Lubricants, NEMA-4X Electrical/Control Items, Stitch Welded Construction

Hygienic Level III for Dry to Wet Environments – Stainless Steel 2B Mill Finish Frame/Legs or Drum, Stainless Steel Shafts with FDA Materials, Stainless Steel Washdown Drive or Power Unit, Stainless Steel Hydraulic Cylinders, FDA Belting, FDA-H1 Lubricants, NEMA-4X Electrical/Control Items, Continuously Welded Construction

About Us

Triton Innovation, LLC. is a leader in manufacturing and supplying equipment for a broad range of food handling and washdown applications. We pride ourselves in working with our clients to develop innovative solutions for food processing operations from handling raw ingredients through packaging.

Triton Innovation, LLC