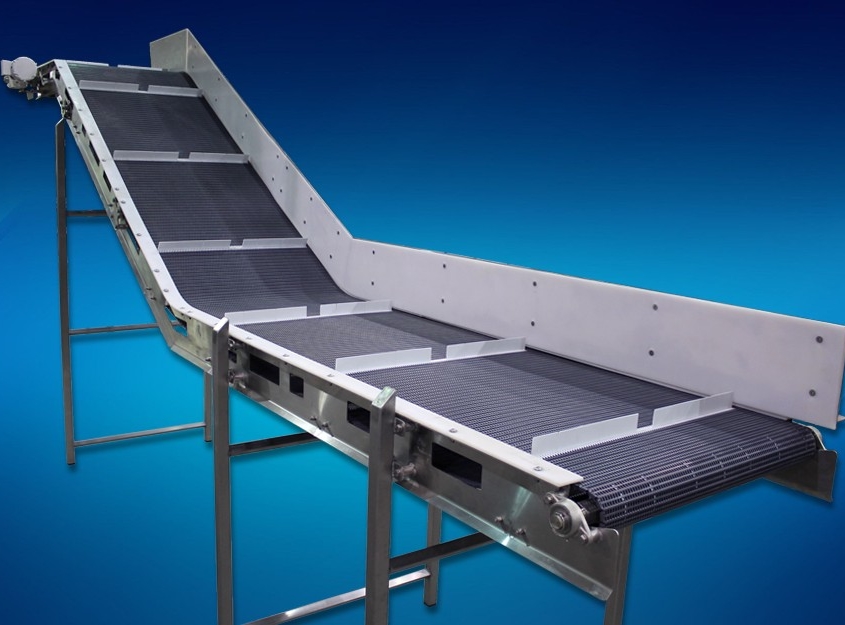

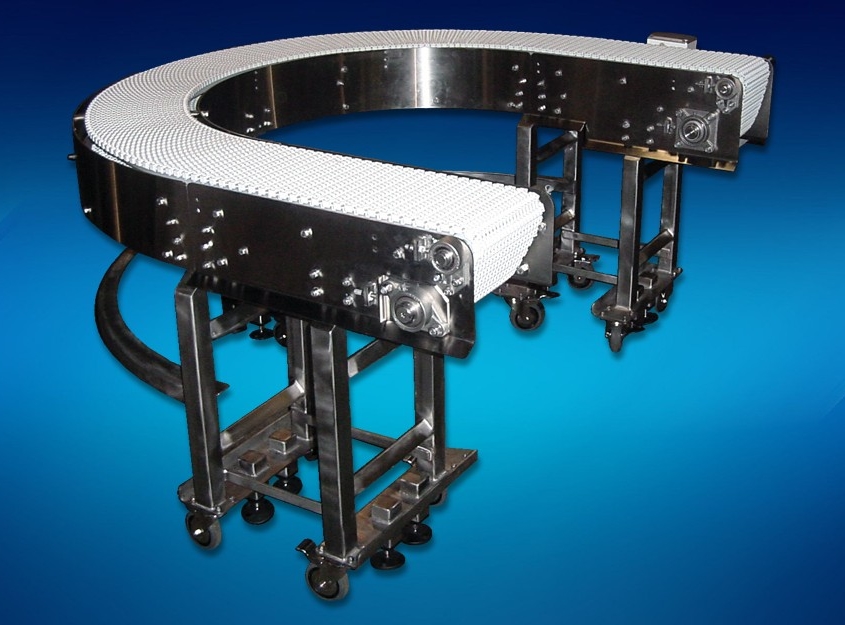

Modular plastic belts are made of plastic modules and are assembled in an interlocked pattern with hinge rods linking them together. Driven by plastic sprockets, plastic belts have many qualities that food plant operators and designers look for. Based on the food application that is desired, each conveyor can be customized by size, belt type, and configuration, as well as many other options. Modular plastic belts are easy to clean and very low maintenance. If a section of the belt is damaged, the damaged modules can be replaced without having to replace the entire belt, lowering costs and the down time typically needed for repairs. From washing to filling to rinsing to inspecting to packaging to transporting, modular plastic belt conveyor has the versatility to fit many food production needs.