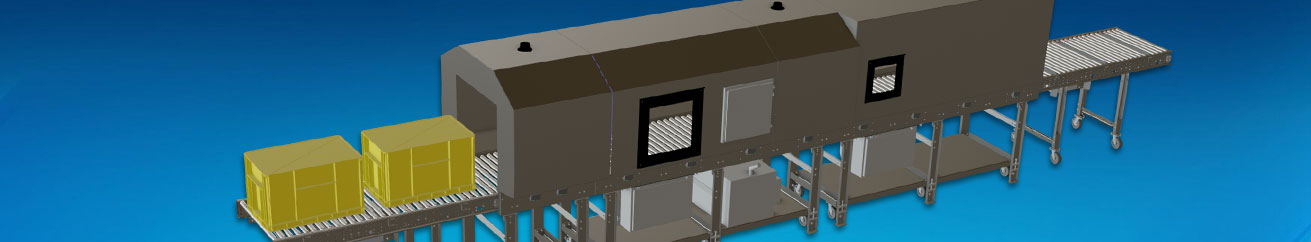

The Triton Innovation LLC Sanitizing Conveyor system offers a sanitizing process for the food processing, package handling, assembly, and manufacturing industries. The system applies a fine mist or spray of sanitizing solution to the surface of products as they move through the conveyor tunnel. The solution is supplied from a central supply line or the system’s reservoir. Benefits workers, customers and carriers by reducing the risk of contamination from goods while receiving, processing, shipping, or storing. This innovative design applies the customer specified and sourced solution to surfaces of goods as they are received, processed, and before they are dispatched or stored.

Design features include:

- Infeed and discharge sensors to start and stop the system automatically

- Belt options suited for boxes, totes, buckets, bags, tins or trays

- Custom widths are available to handle a variety of package sizes

- Drying tunnel to manage the solution dwell and dry times before handling

- Air knives and heat options to reduce dry times

- Drying tunnel design options to increase production rates

- Air scrubbers are available with optional HEPA filters