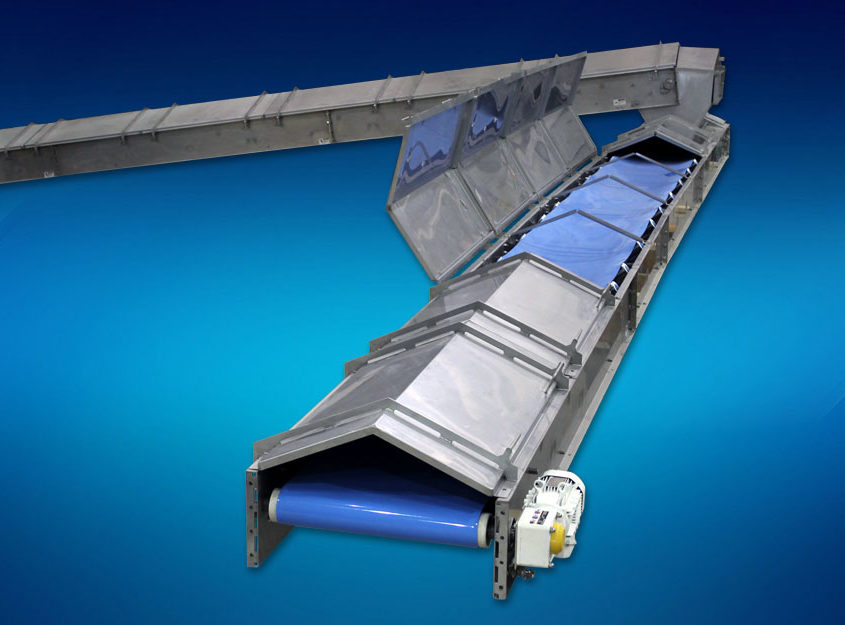

Trough Conveyors are designed to help keep loose or bulk materials in the center of the conveyor. The belt is troughed with rollers, rails, or with a slider bed that the belt conforms to. Trough belts are great for conveying loose or bulk materials, especially if the material is abrasive. Also for conveying long distances while minimizing spillage. From corn meal flour to bulk pretzels going to packaging, trough conveyors have advantages for a wide variety of applications. Inclined and horizontal conveyor configurations are available in white FDA epoxy powder coated, 304 or 316 stainless steel construction.

Design features include:

- Belts – smooth top, rough top, cleated

- Horizontal or incline

- Belt cleaners

- Top covers

- Drip pans

Troughing Styles

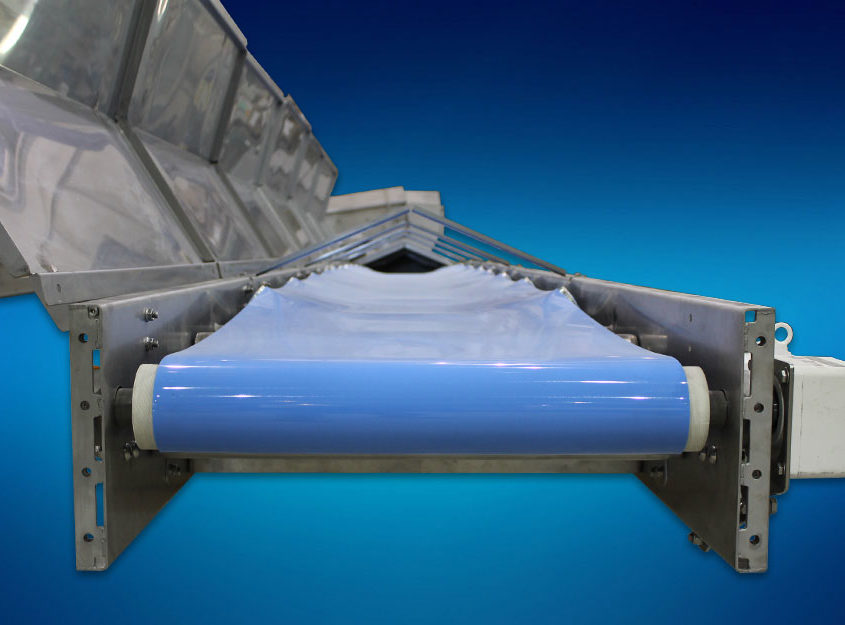

TROUGH RAIL

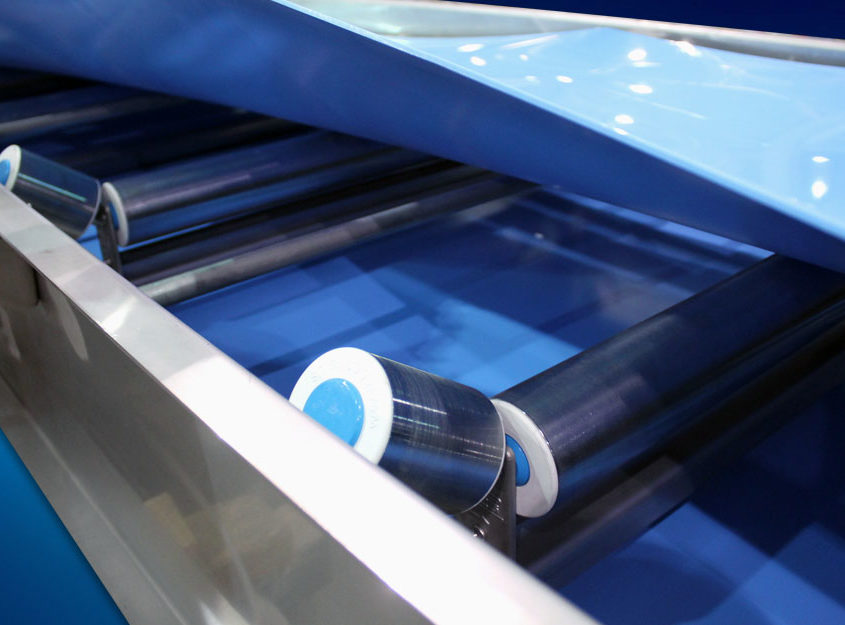

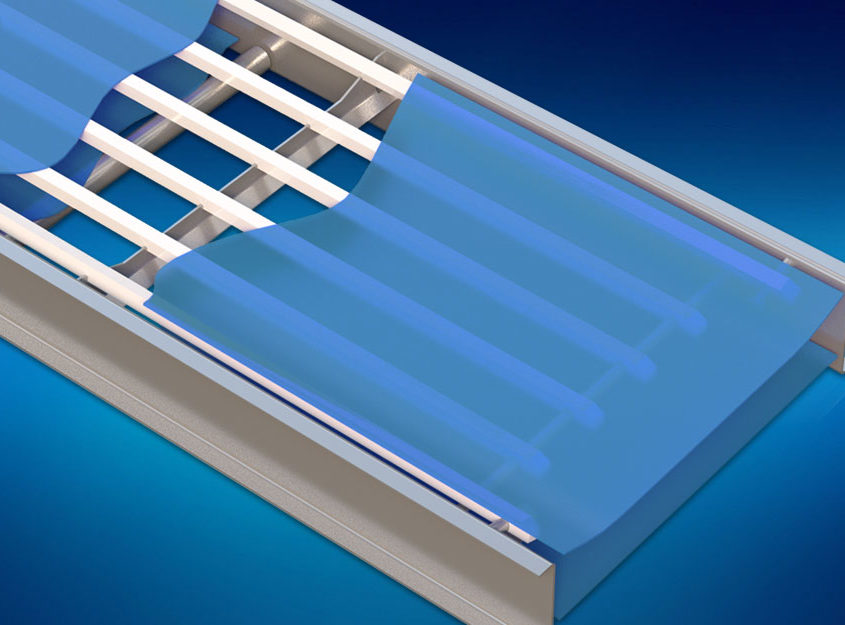

TROUGH ROLLER

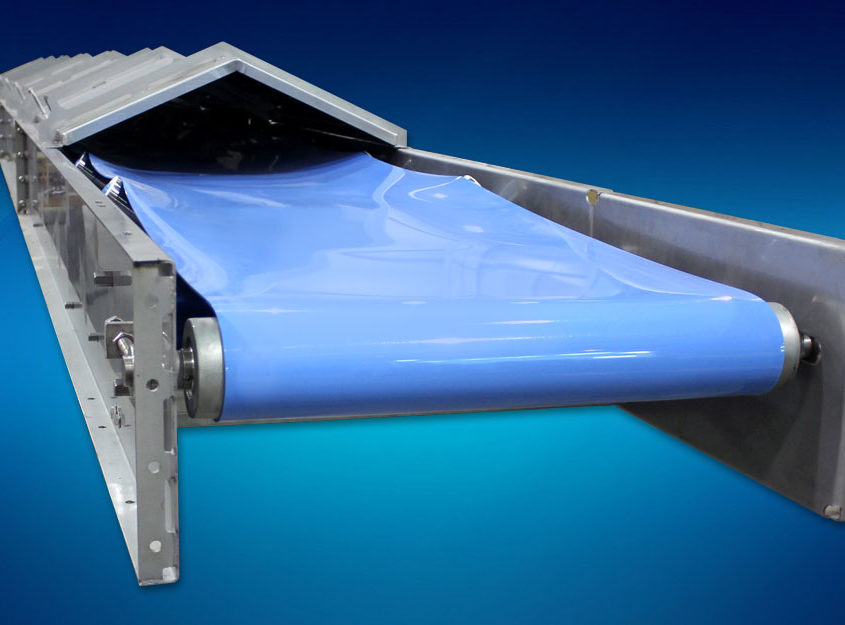

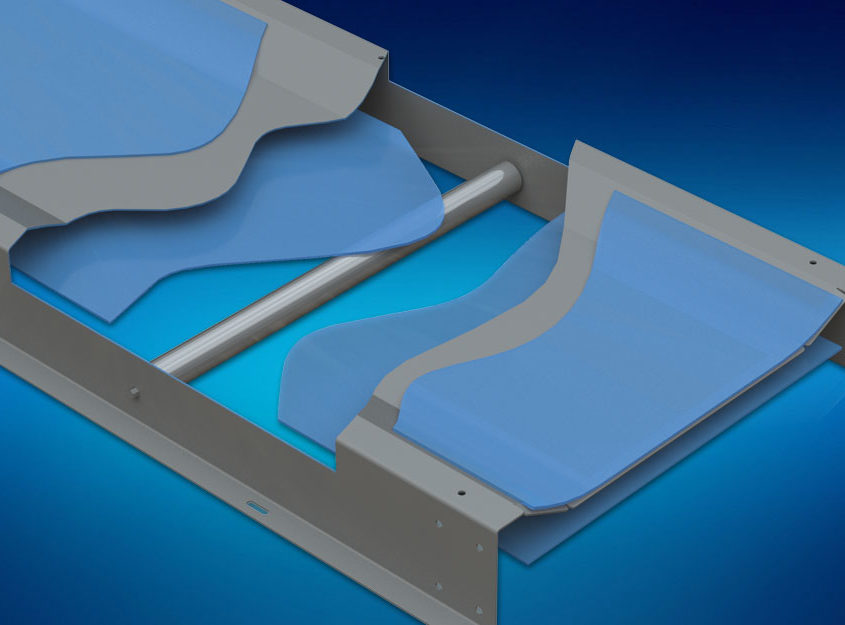

TROUGH SLIDER PAN