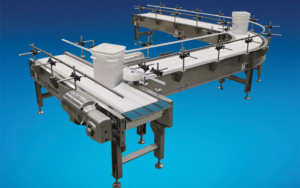

Triton’s Dual Lane Conveyor Doubles Production for Feta Cheese Filling Lines

Application specialists from Triton Innovation, LLC. learned that a customer in New York’s existing operation consisted of a single line that included a filling station, a metal detector, and a lidding station for their feta cheese packaging process. With the addition of a second filling station, this customer needed a cost-effective solution that would integrate seamlessly with their current line to transport, position, and merge tubs of varying sizes from two filling lines into a single scanning and lidding line.

Discover the inventive solution that helped this customer double their production rate by clicking below.

For additional information contact TRITON INNOVATION, LLC – P.O. Box 453, Alpena, MI 49707 | 989.358.6238

Click below to view more about this solution.

#TritonInnovationLLC #TritonInnovation #FetaCheeseProductionLine #FetaCheeseFillingLine #FetaTubs #FetaCheese #BulkFood #FoodHandling #HygienicConveyor #HygienicSolution #FoodManufacturing #FoodProduction #BumpTurn #DualLaneConveyor #CheesePackaging #CheeseFillingLine #DairyProcessing #FoodManufacturingEquipment